how to h8li?

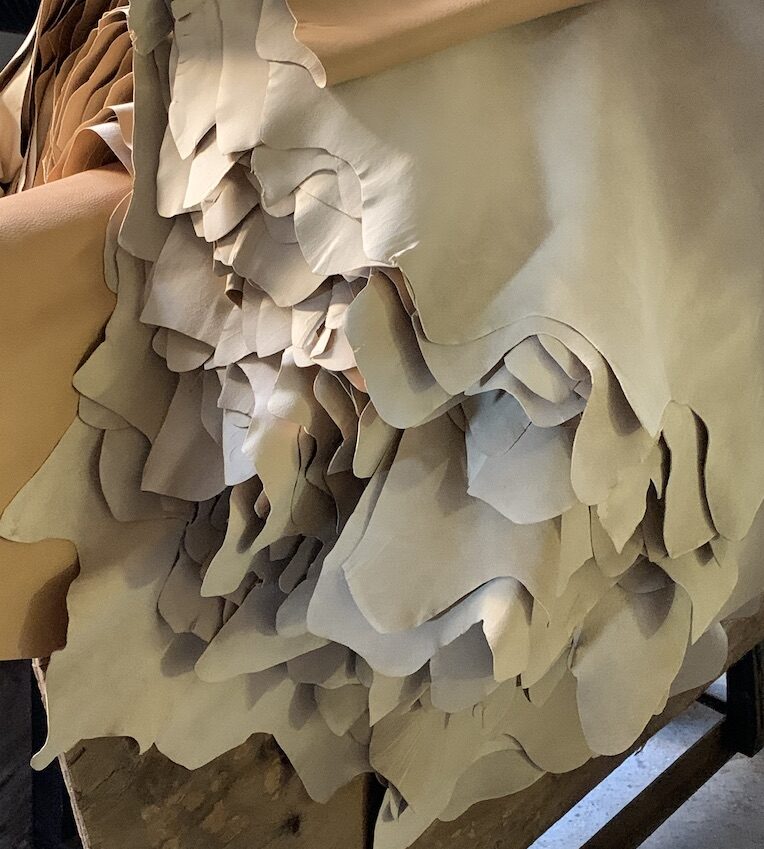

The French choice

French choice is essential. I choose my velvet and leather skins from a butcher located in the Tarn region of France. It's a small, family-run, artisanal butcher's shop in a town with a long tradition of craftsmanship.

Our skins

The "entrefinos" breed of sheep is raised in the Pyrenees for the food industry, with respect for the environment and with animal welfare in mind.

Our skins

The "entrefinos" breed of sheep is raised in the Pyrenees for the food industry, with respect for the environment and with animal welfare in mind.

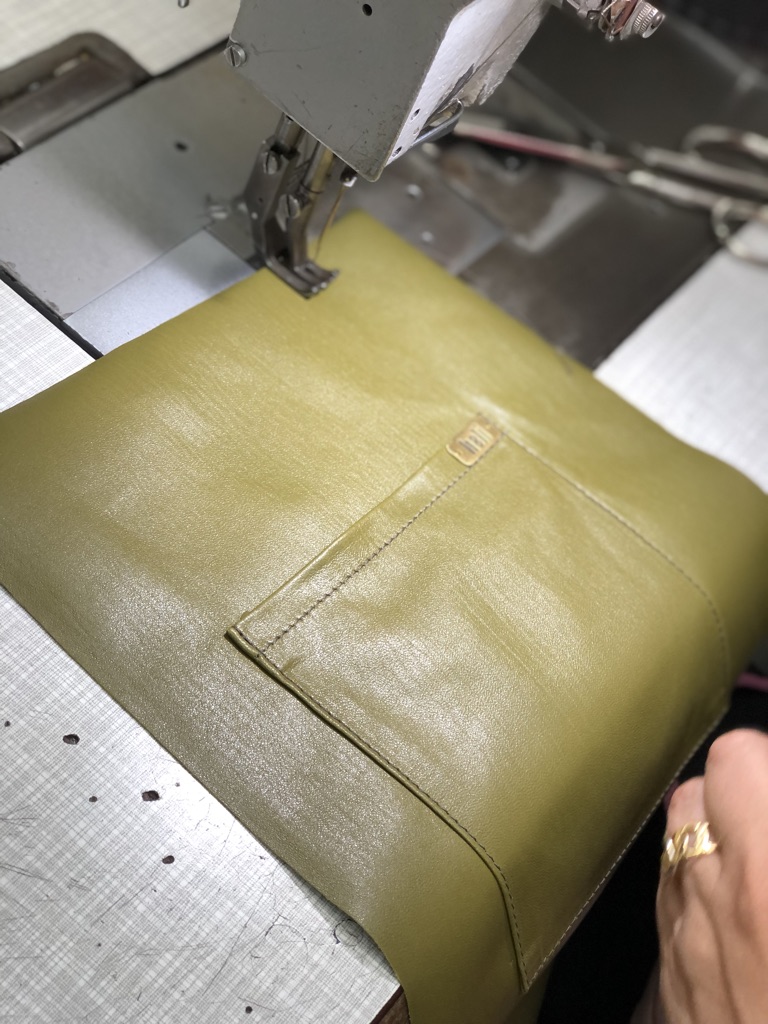

The work of our skins

The skins are then transformed, softened and prepared by Henri and Bertrand, who do the "impossible" to produce the colors I order. In collaboration with a laboratory that researches color formulas.

All colorants and products used comply with German REICH standards.

Finally, the skins are dried by the wind and softened in a fuller to obtain incomparable softness and suppleness.